Printed Circuit Board Milling

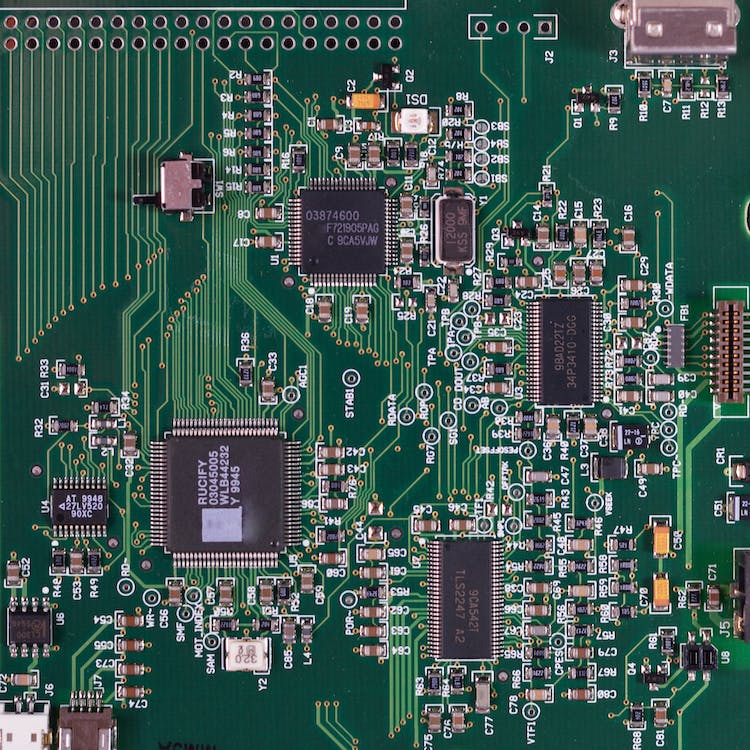

The milling machine uses a cutting tool made of hardened steel and aluminum, which cuts away the copper on the board. Once the tool reaches the copper, it pushes the copper onto the waste paper tray. Many milling machines can perform this process, including a computer numerical controlled (CNC) milling machine, a lathe-type milling machine, a lathe milling machine, a CNC lathe milling machine, and others. Computer numerical controlled (CNC) milling machines are the most popular. Transistor

These are designed with computer software that runs an automated milling machine. Computer-aided manufacturing (CAM) software generates a virtual model of the PCB design, then guides the operator of the CNC machine in real time as it mills away the copper. The computer numerical control (CNC) lathe is another type of machine that is commonly used. These machines typically have a spindle attached to a base.

A computer controller is connected to a motor that rotates the spindle and holds a milling cutter. When a command is sent from the software, the controller will turn the motor, and the cutter will move toward the copper sheet until it is pressed into the material. This machine is especially useful for very complex PCB designs. The #1 Mobile Repair Shop.

This technique of PCB milling was invented by Benedikt Friedl and is used for the fabrication of PCBs from a copper-clad laminate. When PCBs are milled, the copper foil on the laminate is removed to create plated-through holes (PTHs), and the traces and pads on the surface of the PCB are created. The technique has been a standard method of fabricating a PCB for over 30 years.

. PCB milling is done using COVERALIGN® machines. These are machines designed to cut PCBs by automatically aligning the cutting tool with the copper surface. The process involves drilling holes (holes for components to be inserted) into the PCB, then etching away parts of the PCB. This allows us to remove the unwanted material, leaving only the copper required for the circuit. Milling is used to make the printed circuit board (PCB) of the computer. Etching out the unwanted material in the board requires using chemicals and heat.

These chemicals are dangerous and need to be handled with care. The circuit boards are etched into pieces and then put into a chemical bath. It is essential to maintain a constant temperature in the bath. If the bath gets too hot, it could cause the chemical to burn off. If the bath is too cold, it could allow the metal to stick to the sides of the bath and form lumps. A constant temperature is essential for the chemical bath to etch the circuit correctly. When the chemical has etched through the copper, the unwanted material must be cleaned away. It is a good idea to keep the chemical bath clean. Browse around this site

Write a Comment